Application Overview

The GHL high-speed mixing granulator is a high-efficiency equipment that mixes different powdered materials in one process and produces particles, widely used in industries such as pharmaceuticals, food, and chemical.

Equipment characteristics

★This machine adopts a horizontal cylindrical or conical structure, and users can freely choose.

★The internal surface of the equipment has no dead corners and operates in a closed state, meeting the requirements of "GMP".

★Short granulation time, efficient and energy-saving.

★The particles produced have uniform texture and good flowability, providing the most ideal granular raw material for the tablet pressing process.

★Compared to traditional processes, it reduces adhesive by 25% and shortens drying time.

★Each batch is only dry mixed for 2 minutes and pelletized for 1-4 minutes, which improves the efficiency by 4-5 times compared to traditional processes.

★The entire operation has strict safety protection measures.

★When there is a significant difference between the main drug and the excipients, uniform binding can still be achieved without layering.

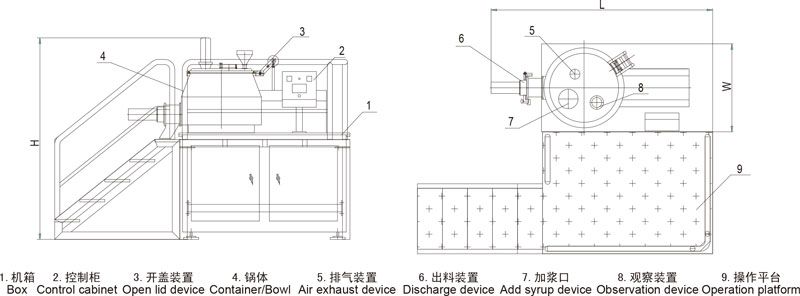

Outline Dimensional Drawing

Specification Items | 2.5/7 | 10 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 600 | 800 | 1000 |

Production capacity (Kg/batch) | 0.3-1 | 3 | 15 | 35 | 50 | 60 | 80 | 100 | 135 | 200 | 280 | 350 |

Particle size (mesh) | 20-80 | |||||||||||

Operation time (min) | 5-7 | |||||||||||

Container volume (L) | 7/2.5 | 10 | 50 | 100 | 150 | 200 | 250 | 300 | 400 | 600 | 800 | 1000 |

Mixing motor power (Kw) | 0.75 | 2.2 | 4/5.5 | 6.5/8 | 6.5/8 | 11/14 | 11/14 | 13/16 | 18.5/22 | 22/28 | 30/37 | 45/55 |

Knife motor power (Kw) | 0.75 | 1.1/1.5 | 1.5/2.2 | 2.2/3 | 2.2/3 | 4/5.5 | 4/5.5 | 4/5.5 | 5.5/7.5 | 7.5/11 | 7.5/11 | 7.5/11 |

Stirring speed (r/min) | 30-950 | 30-950 | 30-340 | 30-320 | 30-300 | 30-280 | 30-280 | 30-230 | 30-180 | 30-180 | 30-180 | 30-120 |

Cutter speed (r/min) | 300/3000 | 1500/3000 | ||||||||||

Compressed air pressure (Mpa) | 0.3-0.6 | |||||||||||

Compressed air consumption (m3/min) | Not have | 0.1 | 0.11 | 0.13 | 0.2 | 0.25 | 0.25 | 0.3 | 0.4 | 0.4 | 0.4/0.5 | 0.5 |

Machine weight (Kg) | 150 | 300 | 400 | 800 | 900 | 1200 | 1500 | 1550 | 1650 | 1800 | 2000 | 2200 |

Main dimensions of the product (Long × wide × Height mm) | 800× 450 × 900 | 1250× 550 × 1160 | 1730× 750 × 1610 | 1950× 750 × 1810 | 1950× 750 × 1810 | 2210× 880 × 2000 | 2210× 880 × 2000 | 2310× 1050 × 2000 | 2485× 1080 × 2050 | 2585× 1400 × 2100 | 2850× 1400 × 2350 | 3140× 1500 × 2800 |

All parameters are for reference only, and our company has the right to make changes based on the material situation without prior notice.