How to achieve joint licenses from multiple large companies and hundreds of successful cases?

Egypt AgrochemLtd LPG-1600

Spain Biochemical Process Claramunt Forner Ltd LPG-300

China Chemical Construction Jiangsu Branch (Export to the Netherlands) LPG-300

VIETFARMCO., Vietnam, LTD.LPG-500

SUNZENFEEDTECH LPG-1300, Malaysia

Slovenia TANINSevnicad.d.LPG-150

Slovenia TANINSevnicad.d.LPG-150

Iceland Algalif LPG-200

Nanjing Jinling Petrochemical Chemical Company LPG-150

Baotou Baosteel China Enterprise Group Co., Ltd. LPG-650

China Yantai Jinzi Food Co., Ltd. LPG-250

Ningbo Siming Pharmaceutical Industry Co., Ltd. LPG-150

Guangzhou Jushengyuan Biochemical Co., Ltd. LPG-150

Changzhou Niutang Chemical Plant LPG-150, Jiangsu Province

Hebei Shuangji Chemical Co., Ltd. LPG-300

Jiangsu Chunzhigu Biological Products Co., Ltd. LPG-300

Zhejiang Tianxin Pharmaceutical Co., Ltd. LPG-150

Zhejiang Huijia Fengmu Biotechnology Co., Ltd. LPG-200

Wuhan Tiantianhao Biological Products Co., Ltd. LPG-300

LPG-1000, Wangtongzhuang Chemical Plant, Gaoyi County, Hebei Province

Shijiazhuang Shiyao Group LPG-150

Jiangsu Nannong Gaoke Animal Pharmaceutical Co., Ltd. LPG-300

Changzhou Jiafa can achieve with reliable products and satisfactory services!

From June 24 to 26, European customers came to our company for a three-day acceptance of centrifugal spray drying equipment and details, and successfully passed the acceptance!

High speed centrifugal spray dryer

Product Overview:

The drying speed is fast. After centrifugal spray, the surface area of the feed liquid increases. In the high-temperature airflow, 95% - 98% of the water can be evaporated instantly, and the drying time is only a few seconds.

Suitable for heat sensitive materials, as droplets flow in the same direction as hot air, although the temperature of the hot air is high, the material will not overheat during water evaporation.

It has a wide range of applications and is used to produce a large number of materials with significant differences in physical properties. Such as polymers and resins; Dyes and pigments; Ceramics and glass: rust removers and insecticides; Carbohydrates; Dairy products; Blood and fish products; Fertilizers; Organic, organic compounds, etc.

The product has good dispersibility, fluidity, and solubility. This is due to the fact that the product can maintain a uniform and fine particle shape by completing drying in an instant.

The production process is simplified and the operation and control are convenient. spray drying is usually used for the solution with a solid content of 40-60%. Even if the content of special materials is up to 90%, they can also be dried into powder products at one time. After most products are dried, they do not need to be crushed and screened again, reducing the production process, simplifying the production process, and improving the purity of products. For the particle size, bulk density, and moisture of the product, the operating conditions can be adjusted and controlled within a certain range, making management very convenient.

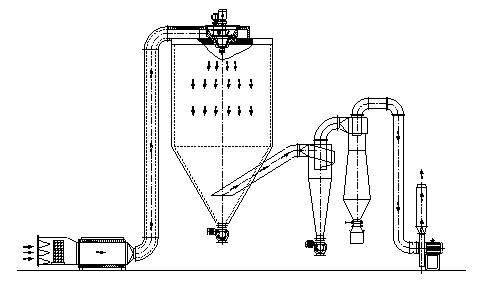

Working principle:

After the air passes through the filter and heating device, it enters the air inlet distributor at the top of the drying chamber. The hot air passing through the air inlet distributor enters the tower in a spiral shape evenly. At the same time, the screw pump sends the feed liquid to the centrifugal spray head installed on the top of the tower body. The feed liquid is atomized into tiny mist droplets, which greatly increases the surface area of the feed liquid in contact with the hot air, and the small droplets and hot air flow and sink together, The water quickly evaporates and is dried into powder products in a very short time, which are captured in the tower bottom and cyclone separator, and the exhaust gas is discharged to the outside world.

Business Consulting: Zou Longgui 13606122988!